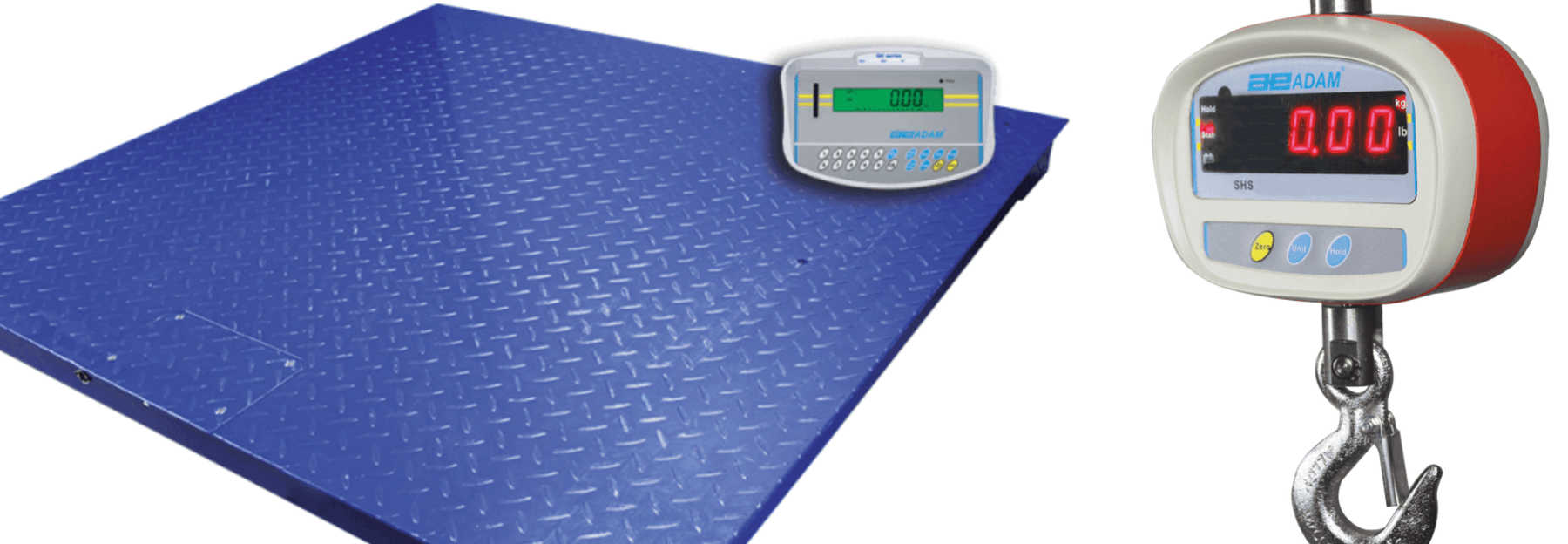

Heavy Duty Weighing Scales: Hanging Scales vs Platform Scales

Your business needs to weigh, and it needs heavy duty weighing scales to do so. And for most industrial weighing applications, if the scale’s capacity needs to be high, platform scales or hanging scales (or crane scales) are used.

But what are the differences between hanging scales and platform scales? And, more importantly, which option is right for you?

Which option you go for will depend on the answers to a number of questions – such as what you’re weighing, where you’re weighing it, and what kind of space you have available in your business for a high capacity weighing scale.

Once you’ve read this bog post, you should know which type of weighing scale is best for you – and, once you’ve purchased said weighing scale, you’ll have something entirely suited to your weighing needs.

Do I need a hanging scale or a platform scale?

We should start by giving you an overview of these two very different types of industrial scales.

Platform scales are large, flat weighing scales built with demanding industrial environments in mind. Their size (usually around 1200mm x 1200mm, but there are many options out there) and shape (flat, square – but sometimes rectangular too!) lends them particularly well to weighing pallets. But, they are ideal for many types of weighing jobs and environments, and most businesses will opt for platform scales when weighing upto 2 tonnes, 3 tonnes and beyond.

Hanging scales rely on suspending an item in the air and measuring the downward force to determine its weight. They also known as crane scales – which, as it happens, is probably a more suitable in the context of this blog post, since hanging scales can also be the small, low-capacity luggage scales you may use at home – or the equally small fish scales you may use if you’re a dedicated fisherman.

How much space do I have?

The first thing to think about when choosing between hanging scales and platform scales is how much space you have available.

Heavy duty weighing scales, since they are designed to weigh large, heavy items, will usually take up a lot of space.

Platform scales need plenty of space – not just for the scale itself, but for loading the scale. You’ll typically use a platform scale in conjunction with a fork truck, which will load palletised goods onto the scale for weighing.

However, if you intend to use your platform scale with pallet trucks, you’ll need to purchase ramps, too – so bear in mind the space you’ll need for these.

It’s worth bearing in mind that, whilst a platform scale is too heavy to be lifted and moved by hand, there are alternatives such as U frame pallet scales that are often a worthwhile (and portable) substitute for a platform scale.

A hanging scale, on the other hand, is suspended from the ceiling, a gantry or crane. This means that, although you will need space to weigh your heavy items, the space required is dictated only by the items you wish to weigh.

Additionally, when not in use, a hanging scale is conveniently out of the way and takes up no floorspace whatsoever.

Where do I need to weigh?

Exactly where you need to weigh your items will dictate the best location for your industrial scale. This can, however, make a big difference in terms of what is easier to use – a platform scale or a hanging scale.

Hanging scales need to be suspended in order to weigh items. So, you need to be able to hang them from something strong enough – like a gantry, for example. In many cases, hanging scales are suspended from a crane hook (here they serve a dual purpose, because they can be used to ensure a crane is not overloaded).

On the other hand, platform scales will not need infrastructure in place to support their use – and (depending on how hardy they are) can be used both inside and outside.

What do I need to weigh?

This is possibly the biggest consideration when choosing between a platform scale and a hanging scale.

Platform scales are perfect for palletised goods. However, they’re also great for weighing other items – they can weigh large boxes, either added to the scale using a fork truck or by hand, and they can weigh items like dolavs, crates and barrels with ease.

Hanging scales are better for more awkwardly-shaped items. Think car engines, scrap metal or coils of wire.

More often than not, hanging scales and platform scales are used to weigh items prior to being loaded onto a lorry. So, if your items are going to be added to a lorry using a fork truck, it might be that a platform scale is better. If your items are going to be craned onto the lorry – consider a hanging scale instead.

Are hanging scales easy to use?

One question we do get asked at Inscale is how easy hanging scales are to use. This shouldn’t be a consideration that deters you from using one or the other – hanging scales are very easy to use, especially those that are sold with a remote control.

Once you have safely attached your item to the hook of the scale, the weight should instantly appear on the reading. Many hanging scales will have a hold function to ‘freeze’ the weight reading on the display.

To find out more about how hanging scales work, please Get In Touch.

Further reading

You can see our full range of hanging scales here.

Want to know more before you buy a platform scale? Read our guide to buying platform scales here.

We elaborate on how to use hanging scales in this blog post.

If you need further help with choosing the right heavy duty weighing scales for your needs, Get In Touch with us.

Leave a comment