Inscale's Guide to Finding the Best Counting Scales

What is a counting scale?

A counting scale is designed to count items placed on a weighing machine, in order to replace manual counting. Have you ever tried counting out two hundred M3 screws? It’s time consuming and so very boring. Imagine having to count 15,000 by hand? It would take ages! So a counting machine is designed to specifically remove that time cost and, let’s be honest, repetitive boredom.

How does a counting scale work?

Now that we know what counting scales will do for us, let’s take a look at how it works. On most dedicated counting scales there will be three displays - 'Weight', 'Piece Part Weight' and 'Total Count’. Weight gives the total weight applied to the scale, piece part weight is the individual average weight of the items being counted and the magic resulting total number of pieces is on the last display. In order to count accurately, counting scales need to be told what item they are counting. This means we first have to weigh a sample. The sample gives the scale two pieces of information, the weight and how many pieces that weight is. So we count a sample of say 25 screws and place them on the pan and the weight was 25g. So the scale knows that the individual weight is 1g, 25g divided by 25 items. Once the scale has this information you can now add screws to reach your target number of pieces, and watch the total count.

Why do I need a counting scale?

Well imagine having to do a stock check by hand, and you have thousands of components to count in your stores. How many hours would be needed to count everything? Also, it’s important to note that the store is likely closed while this job is undertaken, potentially resulting in lost sales. Counting scales remove the need for manual counting and speed up the stock taking processes, saving you time and money. It is said that once you use a counting scale you never go back to manually counting.

So is that it? Should you just buy any counting scale to do your counting? I wish it was that simple, but there are some other factors to add into this. Selecting the right counting scale is also very important, as it would be unfortunate to find that the scale you purchased is not counting correctly and costing you time and money.

Did you know that items that look identical may have different weights? The items may have been made within production tolerances, different material stock or even machining and operator tolerances. So just because the look the same they may not weigh the same. If you do not take into account the tolerances then the error can quickly multiply up when counting your bulk resulting in inaccurate counting.

So how do we avoid this? I have listed some points to consider when selecting the right scale.

3 steps to finding the best counting scale

1) Determine the average piece part weight

Consider your application. If you are going to be counting lots of different items with various weights, first identify the lightest item you will be counting. This will determine the resolution required from the scale. So we have an item we wish to count, take 10 of those items and weigh each one on a precise scale and record the individual weight. Next add those weights together and divide by 10, the result gives you the mean average weight. This takes into account the variations in tolerance of the part. So we now have the average weight for the smallest item being weighed.

2) Determine the maximum weight

So we have an item that we know the average weight of, so how many are we going to count out. Are you bagging say 100 pieces to be sent to production? Or is there 10,000 pieces in the tote bin and you are checking for stock take? Either way the maximum weight is literally the average piece part weight times the quantity. If my box of 10,000 screws had an average weight of 2.5g then the total weight is 10,000 x 2.5 = 25.0kg.

3) Choose your scale

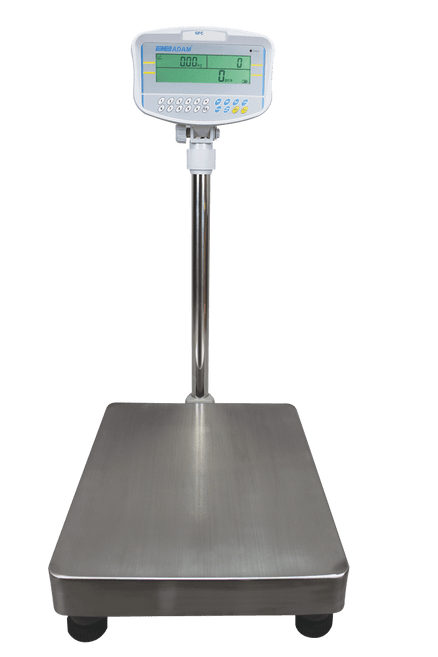

So we know the average weight and the maximum weight, 2.5g and 25.0kg. Now lets determine the capacity of the scale. Our example has an average weight of 2.5g. The counting scale needs to be able to measure this and allow for the variations in tolerance, so it is common place to either divide the average by 10 or half the average weight. In this case we will half the average weight to 1.25g. This means that I will need to look for a scale that will weigh in steps of 1.25g up to or over 25kg in capacity. I know in this case the CBC 32 has a resolution of 1g and a working capacity of 32kg, so this will cover my needs.

|

|

|

| GFC Floor Counting Scale | CCT Bench Counting Scale | Inscale IXC Bench Counting Scale |

Please view our industrial counting scales page. If you require any further information about counting scales, or would like to know more about the products we sell.

Leave a comment