How to Weigh a Pallet

Weighing pallets using specialist pallet scales requires a level of planning and execution to ensure that the task can be completed quickly and safely. For this blog, we look at the three most common forms of pallet scale – the platform scale, pallet truck scale and weigh beams – and give detailed step by step instruction on how to achieve the best results.

What is a pallet truck scale?

A pallet truck scale is a unique weighing instrument that combines a manoeuvrable pump truck with a heavy-duty weighing scale. This means that not only can user weigh their pallets, but they can transfer them around their dispatch department or warehouse floor which greatly saves time. They also offer users a safe method for weighing pallets as they can simply be pushed underneath the pallet before being weighed. It can be said that pallet truck scales do not possess the same high levels of accuracy as other high capacity pallet scales, but do offer incredible convenience that can really speed up repetitive pallet weighing tasks.

How to weigh a pallet on a pallet truck scale

Begin by making sure that your pallet is safe and secure, with the subject in the middle of the pallet to avoid any tipping and help boost accuracy. You will also need to make sure that you are not weighing on a slope or on uneven ground as this can dangerous, and consider that if you want to move your pallet using the scale, you will need a clear route with no obstructions.

Next turn your pallet truck scale on and set up according to your unique operating instructions. You may need to calibrate your pallet scale before use to ensure accurate weighing, or select a weighing function such as checkweighing or parts counting if required. It is also required that you first weigh a pallet without the subject first to tare of the weight.

For this post, we’ll just keep to the regular weighing function. Manoeuvre the pallet truck scale into position and push it underneath the pallet, making sure that the two beams are in the centre of the pallet. Use the handle mechanism to slowly lift he pallet slightly off the ground and read the displayed weight. Either drop the pallet back down to the ground or continue to move it to the desired location. When moving subjects on a pallet truck scale avoid any fast sudden movements that can cause the pallet to tip.

What is a platform scale?

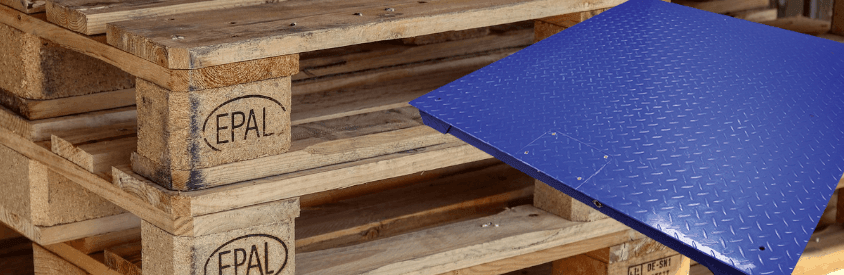

Platform scales are heavy duty, robust industrial scales that lie flat on a warehouse or factory floor. They are large in size, and can some of the highest maximum capacities available on any scale, meaning they are suitable for weighing pallets and other large, heavy objects. Platform scales are often used with a ramp to lift products up onto the platform, with an indicator that is able to be detached and moved to a safe, easy to read area. Their large, flat, heavy duty weighing pans form a stable base for weighing pallets, and are generally more accurate than a pallet truck scale.

How to weigh a pallet on a platform scale

Weighing on a platform scale differs from a pallet truck scale because users will need a forklift truck to lift onto the weighing pan. The setup is much the same as a pallet truck scale – avoid uneven or sloped ground, ensure that your forklift truck has enough room to safely manoeuvre the pallet onto the scale. Users should also calibrate their platform scale and chose the desired weighing function for their application. One thing to note is that platform scales come with a detachable weighing indicator that should be set up in a safe place away from the pallet and forklift truck, i.e. on a stand or attached to a wall.

Next users should begin the weighing process by driving the forklift truck underneath the palleted goods, again ensuring that the forks or in the centre of the pallet. Next slowly lift the pallet, making sure to lift high enough to get over the lip of platform. The pallet can then slowly and safely be dropped onto platform, making sure that it sits firmly in the middle and is not hanging off the edge, before reversing the truck out from underneath the pallet. The user can then check the weight accordingly before moving the subject off and transporting it if necessary.

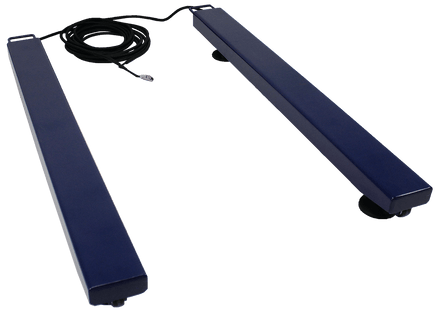

What are weigh beams?

Pallet beams are highly versatile pieces of weighing equipment that can me manoeuvred and used as necessary, thanks to their unique design of two separate weighing beams. These heavy-duty instruments are separated into two selections, parallel or dual beams and U-frame pallet beams and you can use either pallet beam as is or combine with other platforms to expand weighing options. This design enables weigh beams to expand or retract in size when weighing different sized subjects – handy if you regularly weigh different types of pallet sizes or need a versatile weighing scale for weighing other subjects.

How to weigh a pallet on weigh beams

Weigh beams are similar to platform scales in the way that they require a forklift truck to lift a pallet onto the instrument, and again the set up is the same in the way that they should be used on a flat, level surface. The main difference with setting up weigh beams is that they are capable of being made bigger or smaller depending on what is being weighed, so it’s essential that they are set up to suit the right pallet size.

Other than this, the weighing process is exactly the same as a platform scale – use the forklift truck to safely move the pallet up onto the beams and check the indicator for the weight reading.

If you require anymore help with using an industrial pallet scales, please contact a member of our team and we’ll be happy to help. Our phonelines are 01908 972660, or you can Get In Touch with us.

Leave a comment