Bench Scale vs. Floor Scale: Which is Right For Me?

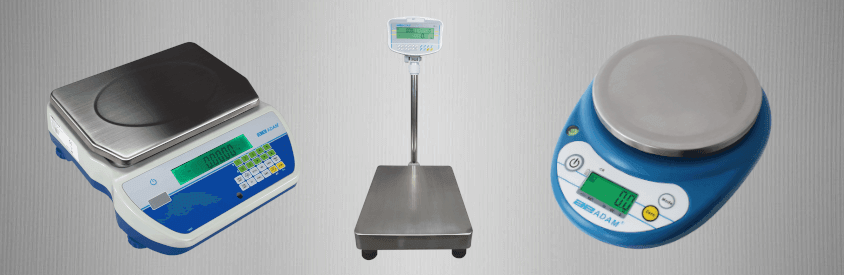

Bench scales and floor scales are similar weighing instruments and can often be interchangeable with each other. Both of these weighing instruments can come with a wealth or features such as checkweighing or parts counting, and both can come with IP ratings and trade approvals for selling by weight.

Even still, each possesses its own set of characteristics that can make them more suitable to certain tasks – let’s dig a little deeper.

What is a bench scale?

A bench scale is a small, compact weighing device that can be used on a counter top, work surface or bench. They are extremely versatile and can come with a small, compact design with integrated display and keypad, or with a larger platform and detachable indicator. Bench scales do not offer the high capacities of say a floor scale, but also do not offer the precision of a precision or analytical balance for example – they are instead made for general weighing tasks.

What is a floor scale?

As the name suggests, a floor scale is a type of weighing instrument that can be used on a floor, such as a production or warehouse floor. They do not offer the same maximum capacities as platform scales or weigh beams, although do tend to offer a higher maximum capacity’s than a bench scale. They are commonly designed with a generous weighing platform with a detachable indicator that can be mounted elsewhere on a wall or stand.

Where are bench scales used?

Bench scales are hugely versatile instruments and can be found in a range of different industries and environments. Unlike floor scales, food services such as restaurants, food productions and catering companies commonly use bench scales to weigh out ingredients or food items for selling.

Industrial and commercial industries also commonly use bench scales, especially when they have specialist features such as checkweighing or parts counting. These features can be useful for repetitious weighing tasks such as production line weighing, end of year stock taking or weighing items for shipping.

Thanks to their small size and easy-to-store designs, bench scales are also found in educational environments such as schools and universities. Whilst precise instruments such as analytical balances are used for more advance weighing, bench scales can be useful for teaching basic weights and measures and doing uncomplicated classroom weighing tasks.

Where are floor scales used?

Like bench scales, floor scales are very versatile and feature durable and robust designs. They are mostly found in industrial and commercial environments where they may be used to weigh heavy or bulky items such as boxes, crates or sacks. When combined with a checkweighing or parts counting feature, they too can be used for stocktaking on inventory monitoring, and are frequently used in shipping departments and dispatch areas for checking the weights of parcels, sacks and crates before transport.

Floor scales can also be found in agricultural environments where they can be used to weigh out heavy subjects like animal feeds, yields or smaller animals. Their hardy builds lend themselves to tough agricultural settings where a long lasting, easy to clean scale is necessary, with many being IP rated for extra protection from dirt, dust, animal feeds or liquids.

What are the benefits of using a bench scale?

Bench scales are smaller than floor scales and are therefore better for users who are pushed for space. For environments without a large amount of floor space, such as cramped workshops or kitchens, bench scales can be good options as they have a smaller footprint, and are often highly portable and can be stacked and stored easily.

Bench scales also come in a greater variety of shapes and sizes which means you’re always likely to find one that’s just right. Compact weighing scales such as the Adam CBX Compact Bench Scales are great for simple weighing tasks such as food portioning, whilst the Adam AGB Large Bench Scale would be ideal for more demanding industrial environments where a larger, higher capacity scale is required.

If you’re undecided about buying either a floor or a bench scale, thought should be given as to where you’re going to be using your scale. For weighing on production lines on raised areas, it doesn’t make sense to have a floor scale where constantly bending down to weigh could be unsafe and inefficient.

What are the benefits of using a floor scale?

Floor scales offer one thing that a bench scale struggles to give: high capacity. They are made for more heavy-duty weighing applications, so anyone that requires higher capacity weighing should opt for a floor scale. Maximum capacities can go up to the 600kg mark which is suitable for very heavy industrial weighing, and most floor scales feature generous sized weighing pans that can make weighing large, awkward sized subjects easier.

Heavy items can also easily be lifted up and onto the weighing pan, which is both safer and simpler than trying to lift heavy items up onto a bench. This also makes weighing subjects from a trolley quick and efficient.

For any more help finding the right floor scale or bench scale for you, please Get In Touch with us.

Leave a comment